Steel Bridge Expansion Joints

Technical Specifications

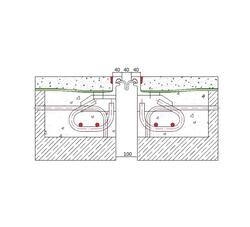

Steel bridge expansion joints are consisting of a waterproof rubber gasket and steel profiles to absorbe movements. This system can be manufactured according request of customer by using extrusion profiles or welded profiles.

Steel used in the edge of the joint element, and all the anchor elements (anchor plates, anchor hoops) minimum DIN ST 37-2 (EN 10025 S235JRG2) quality. Multi-span joints, middle longitudinal profiles, the minimum DIN ST 52-3 (S355J2G3 EN 10025) quality is selecting.

Expansion joints up to 12 m is produced one piece, when joints is exceeding 12 m length by the approval of costumer shall consist of two parts. Necessary joints should chosen out of impact of vehicle traffic areas or minimum impact of vehicle traffic areas.

Against corrosion surface cleaning of steel profiles will be sand blasted with quality of sa2 1/2 and without waiting primers will be applied. At least 80 microns of zinc based primer and at least 100 microns chlorinated rubber or epoxy resin coating paint will be applied against to rust of external influences.

All rubber (NR-CR) elements of expansion joints has produced according with the relevant EN and / or DIN and TSE standards.

Steel bridge expansion joints are consisting of a waterproof rubber gasket and steel profiles to absorbe movements. This system can be manufactured according request of customer by using extrusion profiles or welded profiles.

Steel used in the edge of the joint element, and all the anchor elements (anchor plates, anchor hoops) minimum DIN ST 37-2 (EN 10025 S235JRG2) quality. Multi-span joints, middle longitudinal profiles, the minimum DIN ST 52-3 (S355J2G3 EN 10025) quality is selecting.

Expansion joints up to 12 m is produced one piece, when joints is exceeding 12 m length by the approval of costumer shall consist of two parts. Necessary joints should chosen out of impact of vehicle traffic areas or minimum impact of vehicle traffic areas.

Against corrosion surface cleaning of steel profiles will be sand blasted with quality of sa2 1/2 and without waiting primers will be applied. At least 80 microns of zinc based primer and at least 100 microns chlorinated rubber or epoxy resin coating paint will be applied against to rust of external influences.

All rubber (NR-CR) elements of expansion joints has produced according with the relevant EN and / or DIN and TSE standards.

Rubber Bridge Expansion Joints

Technical Specifications

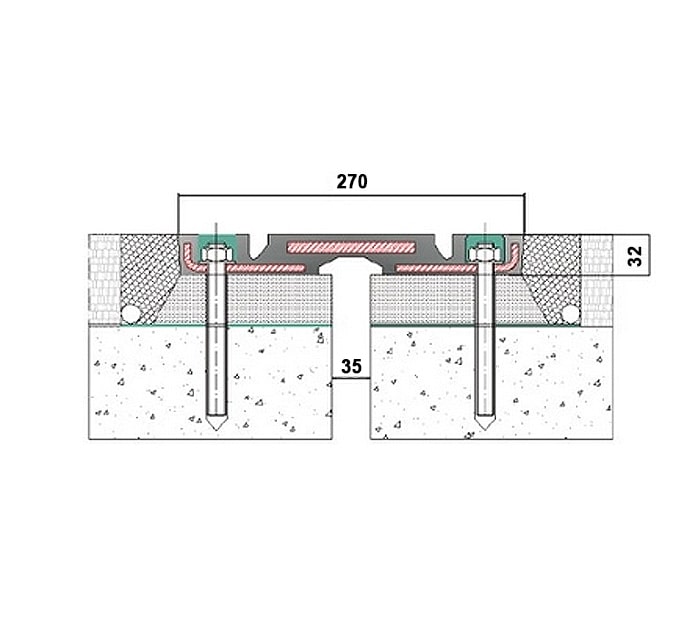

Rubber bridge expansion joints used for 35 mm movements, consisting of a waterproof rubber and steel plates, absorbs movements of the bridge. This system produces in factory under high temperature and pressure with rubber plates and steel plates. This is a result of the production system, our bridge expansion joints, guaranteed against corrosion for long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to UV rays, snow and salt. All expansion joints are designed to absorb movements and expansions of the structure by changing their shape. Expansion joints of different sizes are fixed to the reinforced concrete from both sides by using of suitable corrosion-resistant galvanized anchor bolts and chemical anchors to absorb elastic reactions, mechanical vibrations and other movements of the structure.

Rubber bridge expansion joints used for 35 mm movements, consisting of a waterproof rubber and steel plates, absorbs movements of the bridge. This system produces in factory under high temperature and pressure with rubber plates and steel plates. This is a result of the production system, our bridge expansion joints, guaranteed against corrosion for long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to UV rays, snow and salt. All expansion joints are designed to absorb movements and expansions of the structure by changing their shape. Expansion joints of different sizes are fixed to the reinforced concrete from both sides by using of suitable corrosion-resistant galvanized anchor bolts and chemical anchors to absorb elastic reactions, mechanical vibrations and other movements of the structure.

Elastomeric Bearings

Technical Specifications

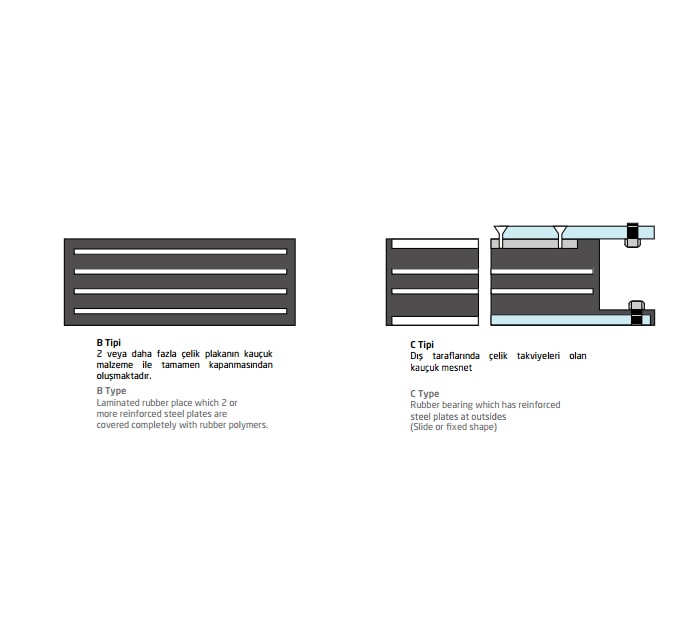

Elastomeric (neoprene) bearings, consisting of a waterproof rubber and steel plates which transfers the loads rightly from capbeams to the bridge columns . This system produces in factory under high temperature and pressure with natural rubber (NR) or chloroprene (CR) plates (in some cases only rubber) and steel plates . Steel plates vulcanized with neoprene material therefore compozite and strong system has been obtained for loads. This production system is giving to bridge bearings, corrosion-guaranteed long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to uv rays, snow and salt. All of these bearings designed and manufactured accordance with recent technology to transfer every kind of loads (traffic load, seismic load, wind load, etc.) from the upper structure to the legs of the bridges.

If sliding bearing requested, it can be designed according to standards using PTFE and stainless steel by our professional engineers.

Our production is manufactured in accordance with BS 5400, DIN 4141, TS EN 1337-3 and AS 5100-4. Bearing selection can be done from tables in EN 1337-3 or related design needs can be sent to our company to produce special sizes for your need.

Elastomeric (neoprene) bearings, consisting of a waterproof rubber and steel plates which transfers the loads rightly from capbeams to the bridge columns . This system produces in factory under high temperature and pressure with natural rubber (NR) or chloroprene (CR) plates (in some cases only rubber) and steel plates . Steel plates vulcanized with neoprene material therefore compozite and strong system has been obtained for loads. This production system is giving to bridge bearings, corrosion-guaranteed long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to uv rays, snow and salt. All of these bearings designed and manufactured accordance with recent technology to transfer every kind of loads (traffic load, seismic load, wind load, etc.) from the upper structure to the legs of the bridges.

If sliding bearing requested, it can be designed according to standards using PTFE and stainless steel by our professional engineers.

Our production is manufactured in accordance with BS 5400, DIN 4141, TS EN 1337-3 and AS 5100-4. Bearing selection can be done from tables in EN 1337-3 or related design needs can be sent to our company to produce special sizes for your need.

Aluminium Expansion Joints

Technical Specifications

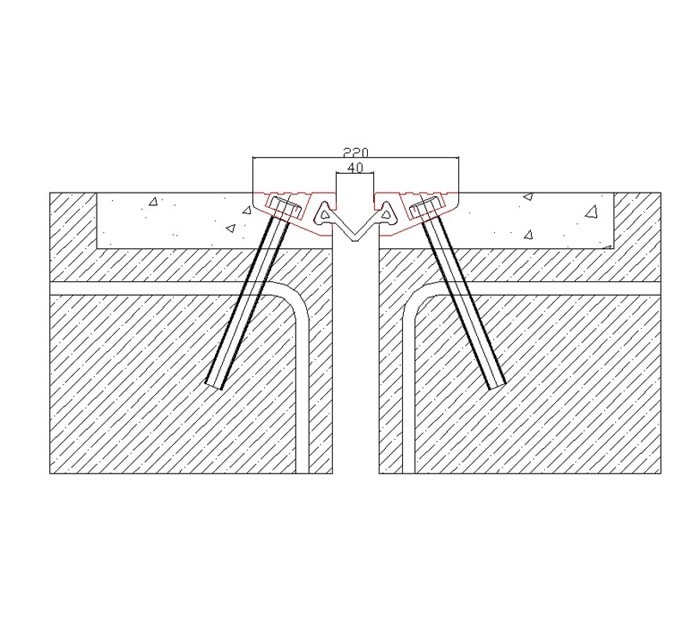

Expansionjoint elements are specially manufactured according to technical needs and benefits of traffic safety. Bridge expansion joints, consisting of a waterproof rubber and special grade of alumium frame, absorbs movements of the bridge. This system produces in factory under high quality conditions.

BE Aluminium Series bridgeexpansion joints, guaranteed against corrosion for long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to UV rays, snow and salt. All expansion joints are designed to absorb movements and expansions of the structure by changing their shape. Expansion joints of different sizes are fixed to the reinforced concrete from both sides by using ofsuitable corrosion-resistant galvanized anchor bolts and chemical anchors to absorb elastic reactions, mechanical vibrations and other movements of the structure. Lateral loads (as a result of the vehicles braking, seismic loads, due to thermal expansion resulting elongation and shortening) is converted.

BE Aluminium Series expansion joints. Itis very easy to repair or change old expansion joints.

RECOMMENDED FOR :

- Sealing of joints in bridges

- Sealing of car parks

- New construction or repair

FEATURES :

• Instalation is easy

• You can choose seal type from 2 difirent model

• Movement Capacity up to 120 mm

• M20 Galvanised Anchors are used

• Continues seal so water tight jointing system

• Frames extruded from speical grade of aluminium

• Smooth passing over the expansion joints do to the flush finish with trafic surface

• Footh path cover plates can be provided if required

• Seals can cover vertical misalignment and limited skew angle

Expansionjoint elements are specially manufactured according to technical needs and benefits of traffic safety. Bridge expansion joints, consisting of a waterproof rubber and special grade of alumium frame, absorbs movements of the bridge. This system produces in factory under high quality conditions.

BE Aluminium Series bridgeexpansion joints, guaranteed against corrosion for long-lasting solution. Rubber is strong against to surface oil, grease, oil, chemicals, resistant to UV rays, snow and salt. All expansion joints are designed to absorb movements and expansions of the structure by changing their shape. Expansion joints of different sizes are fixed to the reinforced concrete from both sides by using ofsuitable corrosion-resistant galvanized anchor bolts and chemical anchors to absorb elastic reactions, mechanical vibrations and other movements of the structure. Lateral loads (as a result of the vehicles braking, seismic loads, due to thermal expansion resulting elongation and shortening) is converted.

BE Aluminium Series expansion joints. Itis very easy to repair or change old expansion joints.

RECOMMENDED FOR :

- Sealing of joints in bridges

- Sealing of car parks

- New construction or repair

FEATURES :

• Instalation is easy

• You can choose seal type from 2 difirent model

• Movement Capacity up to 120 mm

• M20 Galvanised Anchors are used

• Continues seal so water tight jointing system

• Frames extruded from speical grade of aluminium

• Smooth passing over the expansion joints do to the flush finish with trafic surface

• Footh path cover plates can be provided if required

• Seals can cover vertical misalignment and limited skew angle

Modular Expansion Joints

Technical Specifications

Modular expansion joints are composed of multiple parts in order to provide larger movement.

Modular expansion joints are designed taking into consideration the necessary movement capacity and field of application. These joints, the movements may occur in single-span bridge is used when the capacity exceeds the joints.

Mechanically attached rubber gasket allows sealing into the steel profile. In addition, steel components are resistant to corrosion and have high fatigue strength. They have low noise emission.

Modular expansion joints are composed of multiple parts in order to provide larger movement.

Modular expansion joints are designed taking into consideration the necessary movement capacity and field of application. These joints, the movements may occur in single-span bridge is used when the capacity exceeds the joints.

Mechanically attached rubber gasket allows sealing into the steel profile. In addition, steel components are resistant to corrosion and have high fatigue strength. They have low noise emission.

Pot Bearings

Technical Specifications

Pot bearings are designed to carry combinations of the vertical loads, horizontal loads, longitudinal and transversal movements and rotations. These type of bearings can carry very high loads which are over 50.000 kN A completely encased natural rubber pad is positioned in a steel pot. Under high pressure the pad behaves like a liquid. The elasticity of the rubber allows tilting movement (rotation) of the piston in the horizontal axis. Depending on whether the bearing is fixed, guided sliding or a free sliding, pot bearings accommodate vertical loads and corresponding horizontal forces as well as movements in longitudinal or transversal directions.

Fixed Type, These bearings consist of a pot / piston assembly within which an elastomeric disc is encapsulated and fitted with an anti-extrusion sealing device. Under load this encapsulated elastomeric disc acts in a similar manner to a nuncompress-ible confined fluid, enabling the pot and piston to rotate relative to each other. These bearings enable rotation in any direction while at the structure is constrained horizontally. The function of the pot and piston parts are for fixing and securing the bearings to the bridge structure.

Free sliding type, Identical in construction to the fixed bearings, these multi-directional devices are fitted with a virgin PTFE sheet in contact with an austenitic steelplate, enabling the bearing to slide in all directions.

Guided Sliding type, Guided Sliding devices are identical in construction to free sliding bearings but are also fitted with one or more guides to limit the bearings movement to only one direction.

Pot bearings are designed to carry combinations of the vertical loads, horizontal loads, longitudinal and transversal movements and rotations. These type of bearings can carry very high loads which are over 50.000 kN A completely encased natural rubber pad is positioned in a steel pot. Under high pressure the pad behaves like a liquid. The elasticity of the rubber allows tilting movement (rotation) of the piston in the horizontal axis. Depending on whether the bearing is fixed, guided sliding or a free sliding, pot bearings accommodate vertical loads and corresponding horizontal forces as well as movements in longitudinal or transversal directions.

Fixed Type, These bearings consist of a pot / piston assembly within which an elastomeric disc is encapsulated and fitted with an anti-extrusion sealing device. Under load this encapsulated elastomeric disc acts in a similar manner to a nuncompress-ible confined fluid, enabling the pot and piston to rotate relative to each other. These bearings enable rotation in any direction while at the structure is constrained horizontally. The function of the pot and piston parts are for fixing and securing the bearings to the bridge structure.

Free sliding type, Identical in construction to the fixed bearings, these multi-directional devices are fitted with a virgin PTFE sheet in contact with an austenitic steelplate, enabling the bearing to slide in all directions.

Guided Sliding type, Guided Sliding devices are identical in construction to free sliding bearings but are also fitted with one or more guides to limit the bearings movement to only one direction.

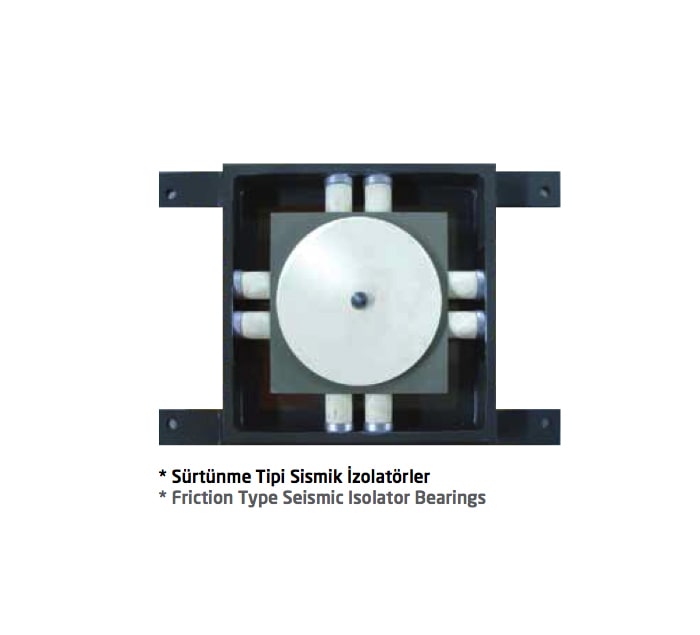

Spherical Bearings

Technical Specifications

Spherical bearing are designed to carry combinations of vertical loads, horizontal loads, longitudinal and transversal movements and rotations and they are used in steel and concrete road and railway bridges. The bearing is composed by steel elements coupled with PTFE surface to allow movement and rotations. One side of the internal median plate is machined as a spherical surface to allow tilting movement (rotation) whilst on the other side a flat sliding surface is obtained to allow displacements. Depending on whether the bearing is fixed, guided sliding or a free sliding, Spherical bearings accommodate vertical loads and corresponding horizontal forces, as well as movements in longitudinal or transversal directions. Spherical bearings are producing accoding to EN 1337-7 but to the clients request they can produced according other codes as well.

Advantages of using Spherical Bearings

Spherical bearings fulfill the following requirements:

» Transmit the vertical loads due to permanent and randomly effects; it is possible to cover a wide range of loads about up from 500 to 100000 kN

» Transmit the horizontal loads with in practise no limitation of the design load

» Allow rotation as per a spherical hinge. The standard design rotation (±0.02 rad) can be easily increased to compensate structure slopes.

» No limitation for horizontal displacement

» Suitable for alltype of structures like steel and concrete bridges and buildings

» High durability andno maintenance

Spherical bearing are designed to carry combinations of vertical loads, horizontal loads, longitudinal and transversal movements and rotations and they are used in steel and concrete road and railway bridges. The bearing is composed by steel elements coupled with PTFE surface to allow movement and rotations. One side of the internal median plate is machined as a spherical surface to allow tilting movement (rotation) whilst on the other side a flat sliding surface is obtained to allow displacements. Depending on whether the bearing is fixed, guided sliding or a free sliding, Spherical bearings accommodate vertical loads and corresponding horizontal forces, as well as movements in longitudinal or transversal directions. Spherical bearings are producing accoding to EN 1337-7 but to the clients request they can produced according other codes as well.

Advantages of using Spherical Bearings

Spherical bearings fulfill the following requirements:

» Transmit the vertical loads due to permanent and randomly effects; it is possible to cover a wide range of loads about up from 500 to 100000 kN

» Transmit the horizontal loads with in practise no limitation of the design load

» Allow rotation as per a spherical hinge. The standard design rotation (±0.02 rad) can be easily increased to compensate structure slopes.

» No limitation for horizontal displacement

» Suitable for alltype of structures like steel and concrete bridges and buildings

» High durability andno maintenance

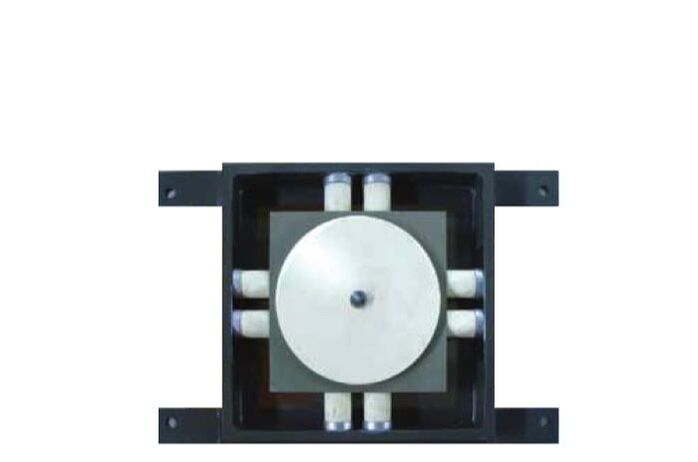

Seismic Isolators

Technical Specifications

Seismic isolation design isconsidered the most effectivedesign technology for protection measures against earthquakes as it is based on the concept of reducing the seismic forces transferred to a structure.

With “seismic isolation design” it is now possible to seismically isolate not only new constructions but also existing constructions through the insertion of special devices between the base of the structure and its foundations

There are lead core rubber bearings, high dumping rubber bearings and friction type bearings according to costumers needs.

Lead Core Rubber Bearings; The lead cylinder facilitates very effective dumpingduring extreme movements. The dumping factor of lead core rubber bearings can be higher then 25%.

High dumping rubber bearings; The high dumping rubber bearings HDRBconsist of multiple elastomer layers made of special dissipative rubber compounds,separated by reinforcing steel plates moulded to the rubber layer, and can be manufactured in a rectangular or circular shape according to customer requirements.

Friction Type Seismic Isolator Bearings; This type seismic ısolators are dumping energy by friction of the materials. This bearings can divided into according their return system like curved (Pendulum type) or plate friction type (eradiquake type)

Seismic isolation design isconsidered the most effectivedesign technology for protection measures against earthquakes as it is based on the concept of reducing the seismic forces transferred to a structure.

With “seismic isolation design” it is now possible to seismically isolate not only new constructions but also existing constructions through the insertion of special devices between the base of the structure and its foundations

There are lead core rubber bearings, high dumping rubber bearings and friction type bearings according to costumers needs.

Lead Core Rubber Bearings; The lead cylinder facilitates very effective dumpingduring extreme movements. The dumping factor of lead core rubber bearings can be higher then 25%.

High dumping rubber bearings; The high dumping rubber bearings HDRBconsist of multiple elastomer layers made of special dissipative rubber compounds,separated by reinforcing steel plates moulded to the rubber layer, and can be manufactured in a rectangular or circular shape according to customer requirements.

Friction Type Seismic Isolator Bearings; This type seismic ısolators are dumping energy by friction of the materials. This bearings can divided into according their return system like curved (Pendulum type) or plate friction type (eradiquake type)

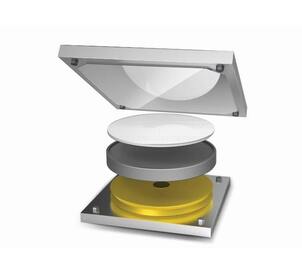

Lead Core Rubber Seismic Bearings

Technical Specifications

Thanks to the high energy dissipation capacity, it is possible to reduce the horizontal displacement, in comparison with that of an isolation system with the same equivalent stiffness but the lower energy dissipation capacity.

LRB is designed for the maximum displacement, from 70%(at ordinary times) of product’s height, 200%(at earthquake times) of product’s height.

If earthquake occurs more than desing force, rubber bearing can respond. Earthaquake forces by protecting their stabilities thanks to their elasticities

Due to elasticity of rubber the structure gets back to the first position as soon as earthquake finishs.

Thanks to the high energy dissipation capacity, it is possible to reduce the horizontal displacement, in comparison with that of an isolation system with the same equivalent stiffness but the lower energy dissipation capacity.

LRB is designed for the maximum displacement, from 70%(at ordinary times) of product’s height, 200%(at earthquake times) of product’s height.

If earthquake occurs more than desing force, rubber bearing can respond. Earthaquake forces by protecting their stabilities thanks to their elasticities

Due to elasticity of rubber the structure gets back to the first position as soon as earthquake finishs.

Seismic Hydraulic Protection Devices (Lock-Up Devices)

Technical Specifications

The hydraulic protection devices (lock-up devices) are basically composed by a cylinder filled by silicon fluid with a movable piston; controlling the fluid flow from one side of the piston to the other it is possible to obtain the required device response law. The device reacts to the imposed relative movement between its connection points that could be between structure and ground or between two internal nodes of a structure.

The hydraulic protection devices (lock-up devices) are basically composed by a cylinder filled by silicon fluid with a movable piston; controlling the fluid flow from one side of the piston to the other it is possible to obtain the required device response law. The device reacts to the imposed relative movement between its connection points that could be between structure and ground or between two internal nodes of a structure.

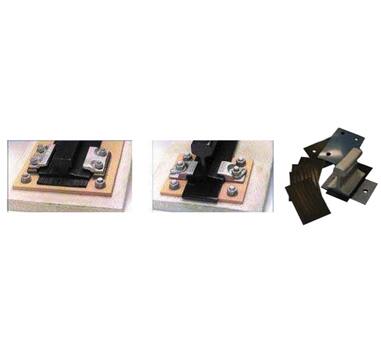

Horizontal Load Bearings

Technical Specifications

Horizontal load bearings are designed to absorb horizontal loads in one or more directions. This type of bearing can be used with elastomeric bearings or free sliding pot bearings.

n this configuration, elastomeric bearings and / or pot bearings support the vertical load, while horizontal load bearings restrain lateral horizontal loads.

Horizontal load bearings are designed to absorb horizontal loads in one or more directions. This type of bearing can be used with elastomeric bearings or free sliding pot bearings.

n this configuration, elastomeric bearings and / or pot bearings support the vertical load, while horizontal load bearings restrain lateral horizontal loads.

Disc Bearings

Technical Specifications

Disc bearings have seen extensive use on railroad bridges as well highway bridges . Disc Bearing are the favorite part for the bridge projects due to the cushioning effect and durability of the polytron rotational element which is designed to handle the excessive live loads typical on railroads and high ways.

Polished Stainless Steel

Stainless steel with a mirror finish provides a low friction sliding interface for the PTFE.

SRM (Shear Resisting Mechanism)

A high strength shear pin transfers horizontal loads from the base plate to the upper bearing plate and isolates shear loads from the polytron disc.

PTFE

The PTFE stainless steel sliding interface results in a very low friction coefficient.

Poliretan Disk

Disc Bearing accommodates design loads of 1 to 100.000kN while maintaining its ability to provide rotation in both longitudinal and transverse directions.

Disc bearings have seen extensive use on railroad bridges as well highway bridges . Disc Bearing are the favorite part for the bridge projects due to the cushioning effect and durability of the polytron rotational element which is designed to handle the excessive live loads typical on railroads and high ways.

Polished Stainless Steel

Stainless steel with a mirror finish provides a low friction sliding interface for the PTFE.

SRM (Shear Resisting Mechanism)

A high strength shear pin transfers horizontal loads from the base plate to the upper bearing plate and isolates shear loads from the polytron disc.

PTFE

The PTFE stainless steel sliding interface results in a very low friction coefficient.

Poliretan Disk

Disc Bearing accommodates design loads of 1 to 100.000kN while maintaining its ability to provide rotation in both longitudinal and transverse directions.

Bituminous Expansion Joints

Technical Specifications

With over 1 million linear metres installed in over 50 countries throughout the world, in conditions from arctic to tropical, Thormajoint is engineered for use across all or part of the road deck – including verges and hard shoulders.

Ennis Flint has developed several grades of binder to meet all climatic conditions. Based on more than 20 years experience, there is no other bridge expansion joint that can beat Thormajoint for effectiveness, economy and reliability.

A special combination of an elastomer modifed BJ200 binder and carefully selected single BJ stone, provide a strength and flexibility that can accommodate horizontal movements up to +/- 40mm

Key Features:

- Quick installation and easy repair

- No mechanical moving parts

- Reduced noise pollution from vehicles travelling over the joint; a smoothriding surface level with existing roadway

- The ability to be surface dressed, to improve skid resistance

- Helps to maintain structural integrity by being watertight

- Adaptability of design to fit installation requirements

- Partial or full installation across carriageways

- Flexibility in all directions, including movement of upto +/-40mm

- Can be used for top-up after resurfacing work, without full replacement

With over 1 million linear metres installed in over 50 countries throughout the world, in conditions from arctic to tropical, Thormajoint is engineered for use across all or part of the road deck – including verges and hard shoulders.

Ennis Flint has developed several grades of binder to meet all climatic conditions. Based on more than 20 years experience, there is no other bridge expansion joint that can beat Thormajoint for effectiveness, economy and reliability.

A special combination of an elastomer modifed BJ200 binder and carefully selected single BJ stone, provide a strength and flexibility that can accommodate horizontal movements up to +/- 40mm

Key Features:

- Quick installation and easy repair

- No mechanical moving parts

- Reduced noise pollution from vehicles travelling over the joint; a smoothriding surface level with existing roadway

- The ability to be surface dressed, to improve skid resistance

- Helps to maintain structural integrity by being watertight

- Adaptability of design to fit installation requirements

- Partial or full installation across carriageways

- Flexibility in all directions, including movement of upto +/-40mm

- Can be used for top-up after resurfacing work, without full replacement

Bridge Deck Preservation

Technical Specifications

Bridge preservation which system is high performance membrane systems designed to permanently protect rail and highway structures. These rapid setting high build elastomeric systems are impervious to deicing chemicals, water, ballast, stray current and other factors that contribute to accelerated deterioration and wear of elevated strucrures and tunnels.

Bridge presevation products are manufactured and certified ISO 9001:2008, insuring that stringent quality control standards are met with each batch of product that leaves our manufacturing facility.

Spray-Applied

Consistent thickness when applied over irregular substrate

Seamless

No seams to seal in order to prevent leaks as you would find with pre-formed sheet membraness

wo-Component System

No powdered catalyst to meausure and add at the jobsite by workers

Non-Sag Consistency

Can be applied Horizontally, Vertically and Overhead

Odorless

Can be used in close proximity to the public and other trades without complaint

Exceeds Requirements

Assurance that the most recent standarts are met

VOC Compliant

Can be used in all states and provinces

Low Permeance

Will not allow water vapors through the membrane. These vapors can condense between the membrane and substrate resulting in freeze/thaw damage to concrete or rusting of steel decking and renforcement.

High Elongation and Low Temperature Flexibility

Will accommodate both low and high temperature substrates

High Tensile Strength and Runcture Resistance

Resists damage from punctures and laceration

Extremely Fast Cure

Can accept ballast and asphalt overlays within one hour of placement

High Electrical Resistance

Electrically isolate decks from stray current

Bridge preservation which system is high performance membrane systems designed to permanently protect rail and highway structures. These rapid setting high build elastomeric systems are impervious to deicing chemicals, water, ballast, stray current and other factors that contribute to accelerated deterioration and wear of elevated strucrures and tunnels.

Bridge presevation products are manufactured and certified ISO 9001:2008, insuring that stringent quality control standards are met with each batch of product that leaves our manufacturing facility.

Spray-Applied

Consistent thickness when applied over irregular substrate

Seamless

No seams to seal in order to prevent leaks as you would find with pre-formed sheet membraness

wo-Component System

No powdered catalyst to meausure and add at the jobsite by workers

Non-Sag Consistency

Can be applied Horizontally, Vertically and Overhead

Odorless

Can be used in close proximity to the public and other trades without complaint

Exceeds Requirements

Assurance that the most recent standarts are met

VOC Compliant

Can be used in all states and provinces

Low Permeance

Will not allow water vapors through the membrane. These vapors can condense between the membrane and substrate resulting in freeze/thaw damage to concrete or rusting of steel decking and renforcement.

High Elongation and Low Temperature Flexibility

Will accommodate both low and high temperature substrates

High Tensile Strength and Runcture Resistance

Resists damage from punctures and laceration

Extremely Fast Cure

Can accept ballast and asphalt overlays within one hour of placement

High Electrical Resistance

Electrically isolate decks from stray current

Poly-tron Elastomeric Concrete

Technical Specifications

Poly-Tron is a fast-setting , low-viscosity , waterproof , moisture-insensitive, 100% solids, modified polyurethane elastomeric concrete material. It consists of three components which include a resin , hardener and aggregate. It’s usage place is especialy in city center high trafic area where has need to repair of expansion joints.

USE

Poly-Tron is fast setting, high performance elastomeric concrete. which is especially uses repair of expansion joint edge materials. It has excellent adhesion to the concrete and steel is flexible yet tough and excellent impact resistance.

USE PLACES

1- Expansion joints edge concrete, repair of old damaged expansion joints. Fixing new expansion joints or repair of damaged concrete of expansion joints.

2- Fixing of steel expansion joint to the structure as a flexible fixing material.

3- Like airport runway or similar places where needs fast repair.

APPLICATION

Application surface must be clean and dry (up to humidity). There won’t be free materials, salt, oil, chemicals on the surface of the deck. Poly-Tron, must applicate directly on the structure (concrete slab or steel deck). Before application primer must used.

Traffic Ready Time

95º-80ºF:1-2 1/2Hours

80º-65ºF:2-3 1/2Hours

65º-45ºF:3-5 1/2 Hours

FEATURES

- Superior adhesion to various substrates

- Excellent resistance to U.V. freeze-thaw, thermal shock, impact, solvents, chemicals and moisture

- Flexible and resilient

- Easy to mix, install, and fast setting

- High quality and economical

Poly-Tron is a fast-setting , low-viscosity , waterproof , moisture-insensitive, 100% solids, modified polyurethane elastomeric concrete material. It consists of three components which include a resin , hardener and aggregate. It’s usage place is especialy in city center high trafic area where has need to repair of expansion joints.

USE

Poly-Tron is fast setting, high performance elastomeric concrete. which is especially uses repair of expansion joint edge materials. It has excellent adhesion to the concrete and steel is flexible yet tough and excellent impact resistance.

USE PLACES

1- Expansion joints edge concrete, repair of old damaged expansion joints. Fixing new expansion joints or repair of damaged concrete of expansion joints.

2- Fixing of steel expansion joint to the structure as a flexible fixing material.

3- Like airport runway or similar places where needs fast repair.

APPLICATION

Application surface must be clean and dry (up to humidity). There won’t be free materials, salt, oil, chemicals on the surface of the deck. Poly-Tron, must applicate directly on the structure (concrete slab or steel deck). Before application primer must used.

Traffic Ready Time

95º-80ºF:1-2 1/2Hours

80º-65ºF:2-3 1/2Hours

65º-45ºF:3-5 1/2 Hours

FEATURES

- Superior adhesion to various substrates

- Excellent resistance to U.V. freeze-thaw, thermal shock, impact, solvents, chemicals and moisture

- Flexible and resilient

- Easy to mix, install, and fast setting

- High quality and economical

Soundproff Wall

Technical Specifications

Soundproof walls are all products reducing the sound pressure with respect to a specified sound source and receptor. Soundprrof walls are to be made by considering the sound absorbing coefficient, transmission loss of sound, insertion loss of sound etc. Depending on used material, soundproof walls are separated by sound absorption type and sound reflection type.

1- Sound Absorption Type

This type is blocking out noise by sound absorption.

Details

Product Size

- Length: 1,960~3,960 mm, Width: 500mm, Thickness: 100mm Absorbing Material

- Polyester (32-60K), t=40~66mm (Repellent treated) -Polyester (over 100K), t=10~30mm (Repellent treated) Front Plate & Rear Plate

- Front Plate: Zinc steel plate, t=0,6~0,8mm

- Rear Plate: Zinc steel plate, t=1,6mm

2- Sound Reflection Type

This type is blocking out noise by sound reflection. It is very useful for securing a clear view. Soundproof panel is made up a main body and separating frame. So ıt is easy to change panels.

Details

Product Size

- Length: 1,960~3,960 mm, Width: 500~1000mm, Thickness: 60~95mm

Transparent Sheet

- Laminated glass or Poly methyl methacrylate Frame

- Aluminum alloyvvv

Soundproof walls are all products reducing the sound pressure with respect to a specified sound source and receptor. Soundprrof walls are to be made by considering the sound absorbing coefficient, transmission loss of sound, insertion loss of sound etc. Depending on used material, soundproof walls are separated by sound absorption type and sound reflection type.

1- Sound Absorption Type

This type is blocking out noise by sound absorption.

Details

Product Size

- Length: 1,960~3,960 mm, Width: 500mm, Thickness: 100mm Absorbing Material

- Polyester (32-60K), t=40~66mm (Repellent treated) -Polyester (over 100K), t=10~30mm (Repellent treated) Front Plate & Rear Plate

- Front Plate: Zinc steel plate, t=0,6~0,8mm

- Rear Plate: Zinc steel plate, t=1,6mm

2- Sound Reflection Type

This type is blocking out noise by sound reflection. It is very useful for securing a clear view. Soundproof panel is made up a main body and separating frame. So ıt is easy to change panels.

Details

Product Size

- Length: 1,960~3,960 mm, Width: 500~1000mm, Thickness: 60~95mm

Transparent Sheet

- Laminated glass or Poly methyl methacrylate Frame

- Aluminum alloyvvv

Others Products

Technical Specifications

Prefabricated Pads : prefabricated pads (bearings) made from rubber, is used for transverse loads from upper structure to lower structure of prefabricated structures.

Speed Barriers (Breakers) : Speed barriers (breakers) are used in places where danger of high speed like intersections, around school and hospital, car parking. Our speed barriers manufactured using high quality rubber is resistant to the passage of the vehicle and weather conditions in the high weight. It is also used different types of groundir.

Railway Pads : Our railway pads made from elastomers, load transfer between rails are used for conditions such as damping the impact. The production can be manufactured in different sizes according to customer demand. By using these pads, rail`s service life is extended. Our railway pads reduce vibration and noise spread around.

Tunnel Segment Gaskets (Seals) : Tunnel segment gaskets, provides isolation between the segment used during tunnel construction.These profiles are produced by Our with high sealing properties, creating a dry surface, enables segments to interlock each other in good shape and prevents damage. These products have long lifetime with high resistance against water pressure and chemical materials.

Rubber Grade (Line) Crossing System : The places where the railroad and highway cutting each atter at same level are called by grade crossing. Rubber grade (line) crossing coatings are used in order to facilitate the passage of the grade crossing road vehicles. Our rubber grade crossings have easy installation and replaceable that does not cause any negativity in traffic. It emits the tyre loads from the vehicle correctly on the ground through traverse and has long service life.

Prefabricated Pads : prefabricated pads (bearings) made from rubber, is used for transverse loads from upper structure to lower structure of prefabricated structures.

Speed Barriers (Breakers) : Speed barriers (breakers) are used in places where danger of high speed like intersections, around school and hospital, car parking. Our speed barriers manufactured using high quality rubber is resistant to the passage of the vehicle and weather conditions in the high weight. It is also used different types of groundir.

Railway Pads : Our railway pads made from elastomers, load transfer between rails are used for conditions such as damping the impact. The production can be manufactured in different sizes according to customer demand. By using these pads, rail`s service life is extended. Our railway pads reduce vibration and noise spread around.

Tunnel Segment Gaskets (Seals) : Tunnel segment gaskets, provides isolation between the segment used during tunnel construction.These profiles are produced by Our with high sealing properties, creating a dry surface, enables segments to interlock each other in good shape and prevents damage. These products have long lifetime with high resistance against water pressure and chemical materials.

Rubber Grade (Line) Crossing System : The places where the railroad and highway cutting each atter at same level are called by grade crossing. Rubber grade (line) crossing coatings are used in order to facilitate the passage of the grade crossing road vehicles. Our rubber grade crossings have easy installation and replaceable that does not cause any negativity in traffic. It emits the tyre loads from the vehicle correctly on the ground through traverse and has long service life.